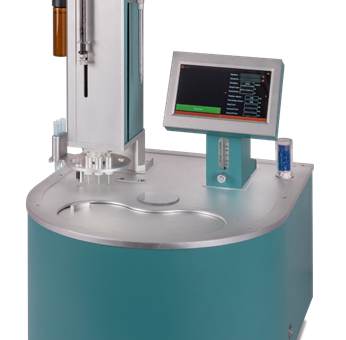

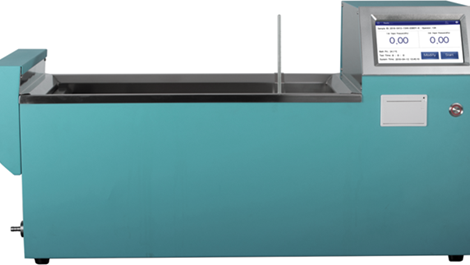

Model

EIE-DI-03Introduction

This instrument complies with the following standard test methods:

- The US ASTM standard methods D86, D850 and D1078

- The European standard method EN ISO 3405

- The British standard methods IP 123 and 195

- The German standard method DIN 51 751

- The French standard method NF M07-002

- The Japanese standard method JIS K2254

- The Chinese standard method GB/T 6536. GB/T 3146.1

- Self-test function after power-on to determine whether to continue testing, and show messages of problem

- High-efficiency refrigeration system, fast cooling rate and light weight

- The flask fast positioning function eliminates the uncertainty caused by positioning errors

- The heater is manually lifted by the lever, which is accurate, convenient and fast. It automatically returns after the measurement.

- The heater plate and the sample group are automatically paired to avoid measurement errors caused by misselection.

- Before starting the measurement, check whether the condenser tube has been cleaned and wiped. If not, the measurement cannot be started.

- Optimized fuzzy PID control algorithm to ensure that the distillation rate of different tested oil products is better than the standard requirements

- Automatic fire extinguishing system, dual-circuit flame detection, automatic start of fire extinguishing function (need to connect to nitrogen or carbon dioxide gas source, gas pressure 700kPa±50kPa)

- The steam temperature measurement unit (steam temperature transmitter) can calibrate the Pt100 sensor and the measuring circuit together, making it easier to send for inspection and making the measured temperature more accurate. It supports 10-point temperature calibration.

- 32bit high-speed ARM processor and embedded real-time operating system ensure that the instrument hardware control has better stability

- Embedded micro IPC, WES7 operating system, a professional control software for instrument control and data analysis

- Automatic dry spot detection by machine vision replaces human eye observation and saves dry spot detection video images for easy analysis and traceability

- 4-inch high-definition color touch industry screen, friendly UI interface, Menu style for easy operation

- Support English and Chinese input the Operator name, Sample name, and support for virtual keyboard input

- Voice prompts for the major step, timely to remind the operator to avoid operational errors

- Glass encapsulated Pt100, compliant with ICE 751, Class A

- High-precision barometer, real-time measurement of atmospheric pressure, automatically participates in steam temperature correction calculation, no manual input required (optional automatic or manual input)

- Real-time display of flask heater temperature, steam temperature and distillation rate curve, and save curve records

- Automatically check key test conditions, including vapor temperature sensor, condenser tube cleaning, heater plate, measuring cylinder, and flask. Avoid deviations in test results caused by human factors or instrument failure

- One-button start, auto-complete determination of the distillation and print the measurement results

- Use Gigabit Ethernet (optional WiFi), RS232 serial port for connection to LIMS systems, real-time data upload realizes laboratory information management

- Built-in mini thermal printer. The results can be printed right after test. Realize rapid data checking and paper copy of data, memos for future reference, worry-free traceability

- According to ASTM D4737 or ASTM D976 standard method, cetane Index value can be calculated from the test result and then saved and printed

Comments are closed.